Dry-type transformers aluminum strip generally use 1060 aluminum alloy, the aluminum content is more than 99.6%, it is also known as pure aluminum and commonly used series of aluminum strip. The advantages of this series are the most commonly used series, the production process is relatively simple, relatively mature technology, the price has a huge advantage relative to other high-grade aluminum alloy. 1060 transformer aluminum strip has good elongation and tensile strength, fully able to meet the conventional processing requirements (stamping, stretching), high molding ability for industrial pure aluminum, with high plasticity, corrosion resistance, conductivity and thermal conductivity, but the strength is low, heat treatment can not be strengthen, the machinability is not good.

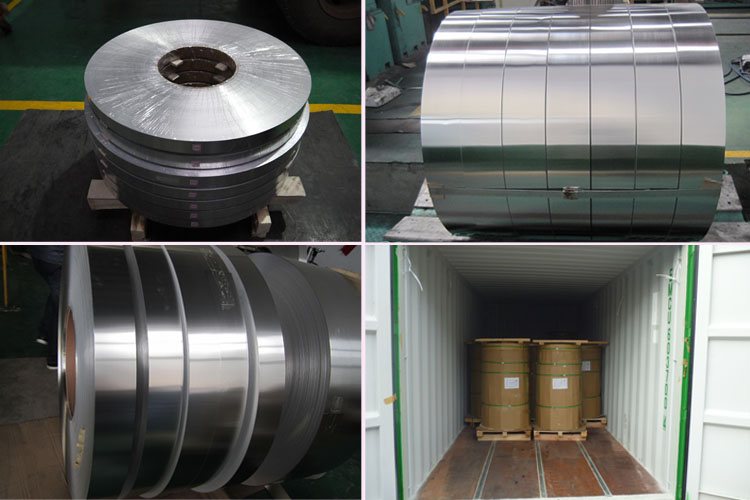

1060 transformer aluminum strip of O temper with high aluminum content, and the conductivity and thermal conductivity is only lower than the conventional copper metal. As the price of copper is much higher than aluminum, so the most commonly used material for the transformer is aluminum strip. Transformer aluminum grades are mainly A1060 (O), mainly used in dry-type transformers, high and low voltage winding used as conductive material. Transformer aluminum strip is mainly used for large transformers, solar energy, power industry. 1060 aluminum alloy becomes the important material in transformer aluminum strip, and Haomei aluminum supply high 1060 aluminum strip for customers, good process control, package and delivery is the assurance of stressful business. As other aluminum products, aluminum strip of Haomei aluminum can be customized as your demand, special specification is ok, please contact us to tell your requirement, we are pleased to help you!

Reprinted from: http://www.aluminium24.eu/new/1060-transformer-aluminum-strip.html